|

1

|

VERIFY IF MALFUNCTION CAUSE IS OPERATION UNDER OPERATION PERMISSION CONDITION

• Perform the power window system initialization procedure.

• Does the driver-side door glass operate automatically using the power window main switch?

|

Yes

|

System is normal. (Tell the customer about power window system initialization procedure.)

|

|

No

|

Go to the next step.

|

|

2

|

POWER WINDOW MAIN SWITCH CONNECTOR INSPECTION

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Disconnect the power window main switch connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 10.

|

|

3

|

POWER WINDOW MOTOR CONNECTOR INSPECTION

• Disconnect the power window motor connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 10.

|

|

4

|

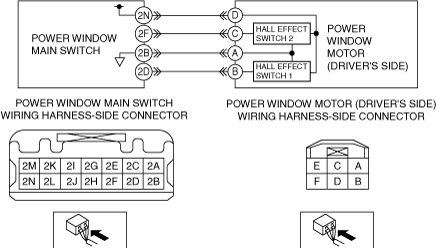

POWER WINDOW MOTOR TERMINAL D INSPECTION

• Reconnect all the disconnected connectors.

• Connect the negative battery terminal.

• Measure the voltage at the power window motor terminal D (vehicle wiring harness side).

• Is the voltage B+?

|

Yes

|

Go to Step 6.

|

|

No

|

Go to the next step.

|

|

5

|

POWER WINDOW MAIN SWITCH TERMINAL 2N INSPECTION

• Measure the voltage at power window main switch terminal 2N (vehicle wiring harness side).

• Is the voltage B+?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between power window main switch terminal 2N and power window motor terminal D.

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open or short circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open or short circuit.

Go to Step 10.

|

|

No

|

Replace the power window main switch, then go to Step 10.

|

|

6

|

DETERMINE IF MALFUNCTION CAUSE IS POWER WINDOW MAIN SWITCH INTERNAL GROUND SYSTEM

• Disconnect the negative battery terminal.

• Inspect for continuity between power window motor terminal A (vehicle wiring harness side) and body ground.

• Is there continuity?

|

Yes

|

Go to Step 8.

|

|

No

|

Go to the next step.

|

|

7

|

VERIFY IF MALFUNCTION CAUSE IS OPEN CIRCUIT IN WIRING HARNESS BETWEEN POWER WINDOW MAIN SWITCH AND POWER WINDOW MOTOR

• Disconnect the power window main switch connector and power window motor connector.

• Inspect for continuity between the following terminals (vehicle wiring harness).

-

? Power window main switch terminal 2B and power window motor terminal A

• Is there continuity?

|

Yes

|

Replace the power window main switch, then go to Step 10.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between power window main switch terminal 2B and power window motor terminal A.

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 10.

|

|

8

|

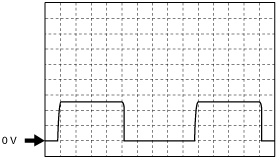

POWER WINDOW MAIN SWITCH TERMINALS 2F AND 2D INSPECTION

• Reconnect all the disconnected connectors.

• Connect the negative battery terminal.

• Measure the pulse at power window main switch terminals 2F and 2D.

• Is the pulse normal?

|

Yes

|

Replace the power window main switch, then go to Step 10.

|

|

No

|

Go to the next step.

|

|

9

|

POWER WINDOW MOTOR TERMINALS B AND C INSPECTION

• Measure the pulse at power window motor terminals B and C.

• Is the pulse normal?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Power window main switch terminal 2D and power window motor terminal B

• Power window main switch terminal 2F and power window motor terminal C

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open or short circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open or short circuit.

Go to the next step.

|

|

No

|

Replace the power window motor, then go to the next step.

|

|

10

|

VERIFY IF MALFUNCTION CAUSE IS CORRECTED

• Does the power window system operate normally?

|

Yes

|

Troubleshooting completed. (Explain the problem to the customer.)

|

|

No

|

Verify the malfunction symptom in the symptom troubleshooting chart and perform the other applicable malfunction diagnosis.

|