|

ON/OFF SOLENOID REMOVAL/INSTALLATION [GW6A-EL, GW6AX-EL]

id0517i2117100

1. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

2. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

3. Clean the transaxle exterior throughout with a steam cleaner or cleaning solvents.

4. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GW6A-EL, GW6AX-EL].)

5. Remove the oil pan.

6. Disconnect the ON/OFF solenoid connector.

am3uuw00008388

|

7. Remove the ON/OFF solenoid.

am3uuw00008389

|

8. Install the ON/OFF solenoid.

am3uuw00008389

|

9. Connect the ON/OFF solenoid connector.

am3uuw00008388

|

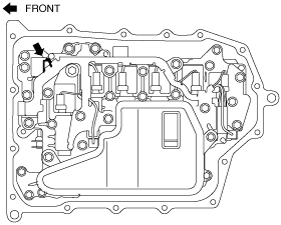

10. Apply a light coat of silicon sealant (TB1217E or equivalent) to the contact surfaces of the oil pan and transaxle case.

am3uuw00008281

|

11. Install the oil pan with new bolts before the applied sealant starts to harden.

ac5wzw00006653

|

12. Install the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

13. Add the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GW6A-EL, GW6AX-EL].)

14. Connect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

15. Perform the “Mechanical System Test”. (See MECHANICAL SYSTEM TEST [GW6A-EL, GW6AX-EL].)