|

1

|

RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the FREEZE FRAME DATA/snapshot data on the repair order.

|

—

|

Go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY RELATED PENDING CODE AND/OR DTC

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Are any other PENDING CODEs and/or DTCs present?

|

Yes

|

Go to the applicable PENDING CODE or DTC inspection.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT EXHAUST GAS PRESSURE SENSOR CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the exhaust gas pressure sensor connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 10.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 10.

|

|

No

|

Go to the next step.

|

|

6

|

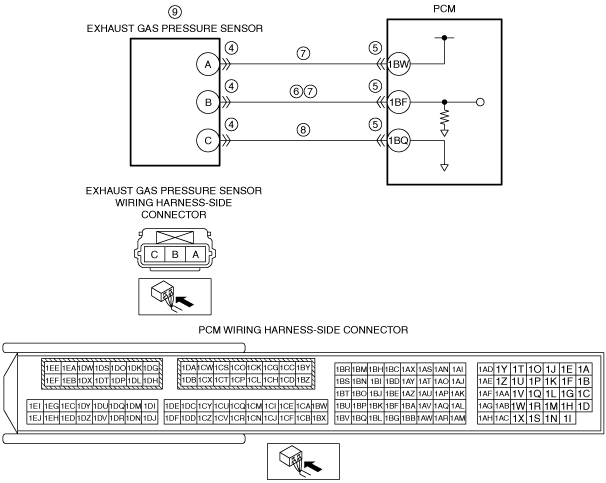

INSPECT EXHAUST GAS PRESSURE SENSOR SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the exhaust gas pressure sensor and PCM connectors are disconnected.

• Switch the ignition ON (engine off).

-

Note

-

• Another DTC may be stored by the PCM detecting an open circuit.

• Measure the voltage at the exhaust gas pressure sensor terminal B (wiring harness-side).

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between exhaust gas pressure sensor terminal B and PCM terminal 1BF.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

Go to Step 10.

|

|

7

|

INSPECT EXHAUST GAS PRESSURE SENSOR POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT FOR SHORT TO EACH OTHER

• Verify that the exhaust gas pressure sensor and PCM connectors are disconnected.

• Switch the ignition off.

• Inspect for continuity between exhaust gas pressure sensor terminals A and B (wiring harness-side).

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Exhaust gas pressure sensor terminal A—PCM terminal 1BW

• Exhaust gas pressure sensor terminal B—PCM terminal 1BF

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to each other.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to each other.

Go to Step 10.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT EXHAUST GAS PRESSURE SENSOR GROUND CIRCUIT FOR OPEN CIRCUIT

• Verify that the exhaust gas pressure sensor and PCM connectors are disconnected.

• Inspect for continuity between exhaust gas pressure sensor terminal C (wiring harness-side) and PCM terminal 1BQ (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between exhaust gas pressure sensor terminal C and PCM terminal 1BQ.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 10.

|

|

9

|

INSPECT EXHAUST GAS PRESSURE SENSOR

• Inspect the exhaust gas pressure sensor.

• Is there any malfunction?

|

Yes

|

Replace the exhaust gas pressure sensor, then go to the next step.

|

|

No

|

Go to the next step.

|

|

10

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Perform the KOEO or KOER self test.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

|

11

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|