|

ac9wzw00004486

ELECTRIC PARKING BRAKE AUTOMATIC RELEASE FUNCTION DURING ACCELERATION MALFUNCTIONS [ELECTRIC PARKING BRAKE]

id040328250600

Description

Possible Cause

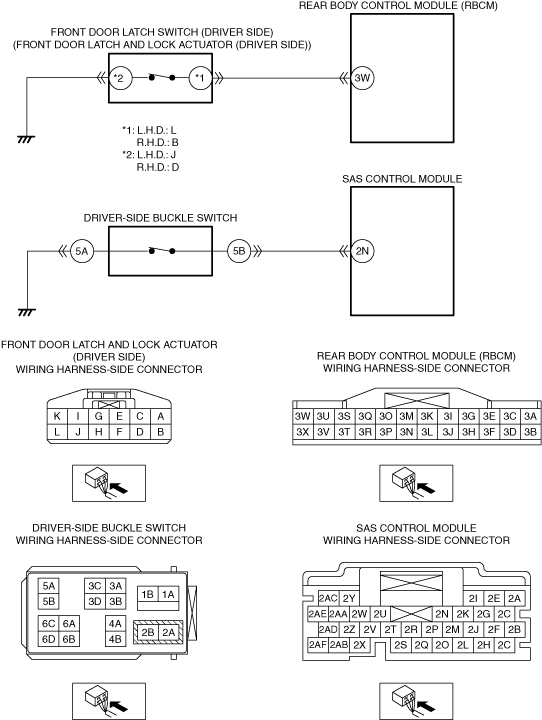

System Wiring Diagram

ac9wzw00004486

|

Diagnostic Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

VERIFY ALL SYSTEM DTCs

• Switch the ignition OFF.

• Switch the ignition ON (engine off or on) and wait for 10 s or more.

• Perform a CMDTC self-test using the M-MDS.

• Are any DTCs displayed?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

||

|

2

|

VERIFY IF THE ELECTRIC PARKING BRAKE WARNING LIGHT IS TURNED ON

• Verify if the electric parking brake warning light is turned on.

• Is the electric parking brake warning light turned on?

|

Yes

|

Perform an inspection referring to “ELECTRIC PARKING BRAKE WARNING LIGHT TURNS ON”.

|

|

No

|

Go to the next step.

|

||

|

3

|

DETERMINE MALFUNCTIONING LOCATION BY PERFORMING PID/DATA MONITOR INSPECTION

• Using the M-MDS, display the following PIDs for the rear body control module (RBCM).

• Using the M-MDS, display the following PIDs for the SAS control module.

• Does the PID monitoring value switch correctly in conjunction with the opening/closing of the front door (driver’s side) or with the driver's seat belt fastened?

|

Yes

|

Replace the electric parking brake control module.

|

|

No

|

Not in conjunction with front door (driver’s side) open/close

• Go to the next step.

Not in conjunction with driver's seat belt fastened

• Go to Step 10.

|

||

|

4

|

INSPECT FRONT DOOR LATCH AND LOCK ACTUATOR (DRIVER’S SIDE) CONNECTOR CONDITION

• Switch the ignition OFF.

• Disconnect the negative battery terminal.

• Disconnect the front door latch and lock actuator (driver’s side) connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

5

|

INSPECT FRONT DOOR LATCH SWITCH (DRIVER’S SIDE)

• Inspect the front door latch switch (driver’s side).

• Is the front door latch switch (driver’s side) normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the front door latch and lock actuator (driver’s side).

|

||

|

6

|

INSPECT FRONT DOOR LATCH SWITCH (DRIVER’S SIDE) GROUND CIRCUIT FOR OPEN CIRCUIT

• Verify that the front door latch and lock actuator (driver's side) connector is disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• L.H.D.

• R.H.D.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit and a poor ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit and a poor ground.

|

||

|

7

|

INSPECT REAR BODY CONTROL MODULE (RBCM) CONNECTOR CONDITION

• Disconnect the rear body control module (RBCM) connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

8

|

INSPECT FRONT DOOR LATCH SWITCH (DRIVER’S SIDE) CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the front door latch and lock actuator (driver’s side) and rear body control module (RBCM) connectors are disconnected.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Measure the voltage at the following terminal (wiring harness-side):

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• L.H.D.

• R.H.D.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

|

||

|

9

|

INSPECT FRONT DOOR LATCH SWITCH (DRIVER’S SIDE) CIRCUIT FOR OPEN CIRCUIT

• Switch the ignition OFF.

• Disconnect the negative battery terminal.

• Verify that the front door latch and lock actuator (driver’s side) and rear body control module (RBCM) connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Replace the rear body control module (RBCM).

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• L.H.D.

• R.H.D.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

||

|

10

|

INSPECT DRIVER-SIDE BUCKLE SWITCH CONNECTOR CONDITION

• Switch the ignition OFF.

• Disconnect the negative battery terminal and wait for 1 min or more.

• Disconnect the driver-side buckle switch connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

11

|

INSPECT DRIVER-SIDE BUCKLE SWITCH

• Inspect the driver-side buckle switch.

(See BUCKLE SWITCH INSPECTION.)

• Is the driver-side buckle switch normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the driver-side front buckle.

|

||

|

12

|

INSPECT DRIVER-SIDE BUCKLE SWITCH GROUND CIRCUIT FOR OPEN CIRCUIT

• Verify that the driver-side buckle switch connector is disconnected.

• Inspect the wiring harness for continuity between driver-side buckle switch terminal 5A (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between driver-side buckle switch terminal 5A and body ground.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

||

|

13

|

INSPECT SAS CONTROL MODULE CONNECTOR CONDITION

• Disconnect the SAS control module connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector.

|

||

|

14

|

INSPECT DRIVER-SIDE BUCKLE SWITCH CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the driver-side buckle switch and SAS control module connectors are disconnected.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Measure the voltage at the driver-side buckle switch terminal 5B (wiring harness-side).

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between driver-side buckle switch terminal 5B and SAS control module terminal 2N.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

|

||

|

15

|

INSPECT DRIVER-SIDE BUCKLE SWITCH CIRCUIT FOR OPEN CIRCUIT

• Switch the ignition OFF.

• Disconnect the negative battery terminal.

• Verify that the driver-side buckle switch and SAS control module connectors are disconnected.

• Inspect the wiring harness for continuity between driver-side buckle switch terminal 5B (wiring harness-side) and SAS control module terminal 2N (wiring harness-side).

• Is there continuity?

|

Yes

|

Replace the SAS control module.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between driver-side buckle switch terminal 5B and SAS control module terminal 2N.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

|

||