|

ac9uuw00009289

AIR BAG SYSTEM WARNING LIGHT ILLUMINATES CONSTANTLY [AIR BAG SYSTEM]

id0803a3814400

|

Description

|

• Air bag system warning light is illuminated constantly and remains illuminated after 6 s have elapsed.

|

|

Possible cause

|

• Weak battery

• SAS control module connectors are poorly connected

• Instrument cluster connector is poorly connected

• SAS control module malfunction

• Instrument cluster malfunction

• SAS control module power supply circuit malfunction

|

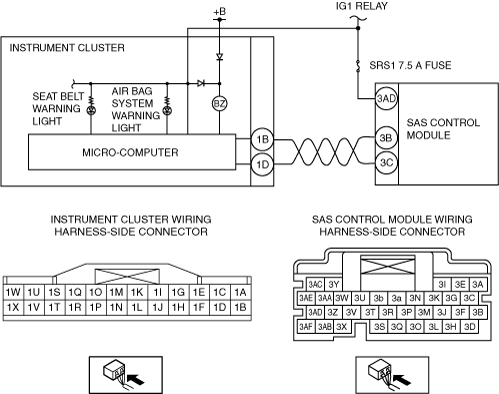

System Wiring Diagram

ac9uuw00009289

|

Diagnostic Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

INSPECT BATTERY

• Measure the voltage of battery.

• Is the voltage more than 9 V?

|

Yes

|

Go to the next step.

|

|

No

|

Battery is weak.

Inspect charge/discharge system, then go to Step 8.

(See BATTERY INSPECTION.)

|

||

|

2

|

VERIFY THAT SAS CONTROL MODULE CONNECTOR IS CONNECTED

• Switch the ignition off.

• Disconnect the negative battery terminal and wait for 1 min or more.

• Remove the selector lever component.

• Are all SAS control module connectors securely connected?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the connector properly, then go to Step 8.

|

||

|

3

|

VERIFY THAT INSTRUMENT CLUSTER CONNECTOR IS CONNECTED

• Disconnect the instrument cluster connector.

• Are all instrument cluster connectors securely connected?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the connector properly, then go to Step 8.

|

||

|

4

|

INSPECT DTCs IN SAS CONTROL MODULE

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Clear the DTC for the SAS control module using the M-MDS.

• Inspect the DTC for the SAS control module on-board diagnostic system.

• Have DTCs been recorded in memory?

|

Yes

|

Perform the applicable DTC inspection, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

5

|

INSPECT DTCs IN INSTRUMENT CLUSTER

• Inspect the DTC for the instrument cluster on-board diagnostic system.

• Have DTCs been recorded in memory?

|

Yes

|

Perform the applicable DTC inspection, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

6

|

VERIFY WHERE MALFUNCTION IS IN WARNING LIGHTS INDICATION CIRCUIT OR ELSEWHERE

• Turn on all warning lights and indicator lights using the instrument cluster PID WL+IL of simulation function using the M-MDS.

• Do other warning and indicator lights illuminate?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the instrument cluster.

Then go to Step 8.

|

||

|

7

|

INSPECT POWER SUPPLY CIRCUIT OF SAS CONTROL MODULE (TERMINAL 3AD)

• Switch the ignition off.

• Disconnect the negative battery terminal and wait for 1 min or more.

• Remove the column cover.

• Disconnect the clock spring connector.

• Remove the glove compartment.

• Disconnect the passenger-side air bag module connector.

• Disconnect the driver and passenger-side seat connectors.

• Remove the B-pillar lower trim.

• Disconnect the driver and passenger-side front pre-tensioner seat belt connectors.

• Remove the trunk side trim.

• Disconnect the driver and passenger-side rear pre-tensioner seat belt connectors.

• Remove the selector lever component. (See AUTOMATIC TRANSAXLE SHIFT MECHANISM REMOVAL/INSTALLATION.)

• Disconnect all SAS control module connectors.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Measure the voltage at SAS control module at wiring harness-side connector terminal 3AD.

• Is the voltage 9.1 V—17.9V?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the SRS1 7.5 A fuse.

If the fuse is blown:

• Refer to the wiring diagram and verify whether or not there is a common connector between SRS1 7.5 A fuse and SAS control module terminal.

If there is a common connector:

If there is no common connector:

• Replace the fuse.

If the fuse is damaged:

• Replace the fuse.

If the fuse is normal:

• Refer to the wiring diagram and verify whether or not there is a common connector between SRS1 7.5 A fuse and SAS control module terminal.

If there is a common connector:

If there is no common connector:

Go to the next step.

|

||

|

8

|

VERIFY THAT MALFUNCTION SYMPTOMS DO NOT RECUR AFTER REPAIR

• Connect the SAS control module connectors.

• Reconnect all disconnected connectors.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Does the air bag system warning light illuminate for approx. 6 s and turn off?

|

Yes

|

Complete troubleshooting, then explain repairs to customer.

|

|

No

|

Recheck malfunction symptoms, then repeat from Step 1 if malfunction recurs.

|

||