|

ac9wzw00005137

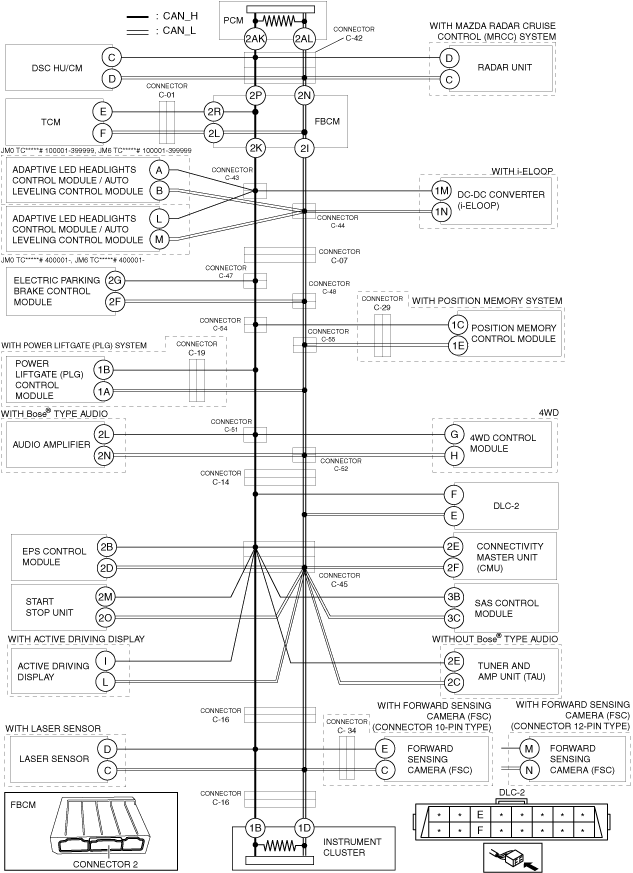

DETERMINING SHORT TO POWER SUPPLY LOCATION (HS-CAN) [R.H.D.]

id100226000700

System Wiring Diagram

ac9wzw00005137

|

Determination Procedure

|

Step |

Inspection |

Action |

|

|---|---|---|---|

|

1

|

INSPECT FOR SHORT TO POWER SUPPLY BETWEEN FRONT BODY CONTROL MODULE (FBCM) AND INSTRUMENT CLUSTER

• Disconnect the negative battery terminal.

• Disconnect connector 2 which has front body control module (FBCM) terminals 2K and 2I

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 11.

|

||

|

2

|

INSPECT CAN LINE BETWEEN TCM AND FRONT BODY CONTROL MODULE (FBCM) FOR SHORT TO POWER SUPPLY

• Measure the voltage at TCM terminals E and F.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECT CAN LINE BETWEEN TCM AND CONNECTOR C-01 FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-01.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at TCM terminals E and F.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between the front body control module (FBCM) and connector C-01 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

4

|

INSPECT TCM FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the TCM connector.

• Connect connector C-01.

• Connect connector 2 which has front body control module (FBCM) terminals 2K and 2I

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the TCM because there is a short to the power supply in the TCM.

|

|

No

|

Repair or replace the wiring harness between the TCM and connector C-01 because the wiring harness is shorted to the power supply.

|

||

|

5

|

INSPECT CAN LINE BETWEEN PCM AND FRONT BODY CONTROL MODULE (FBCM) FOR SHORT TO POWER SUPPLY

• Measure the voltage at PCM terminals 2AK and 2AL.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the front body control module (FBCM) because there is a short to the power supply in the front body control module (FBCM).

|

|

No

|

Go to the next step.

|

||

|

6

|

INSPECT CAN LINE BETWEEN CONNECTOR C-42 AND FRONT BODY CONTROL MODULE (FBCM) FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-42.

• Connect connector 2 which has front body control module (FBCM) terminals 2K and 2I

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the front body control module (FBCM) and connector C-42 because the wiring harness is shorted to the power supply.

|

||

|

7

|

INSPECT CAN LINE BETWEEN DSC HU/CM AND CONNECTOR C-42 FOR SHORT TO POWER SUPPLY

• Measure the voltage at DSC HU/CM terminals C and D.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 9.

|

|

No

|

Go to the next step.

|

||

|

8

|

INSPECT DSC HU/CM FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the DSC HU/CM connector.

• Connect connector C-42.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the DSC HU/CM because there is a short to the power supply in the DSC HU/CM.

|

|

No

|

Repair or replace the wiring harness between DSC HU/CM and connector C-42 because the wiring harness is shorted to the power supply.

|

||

|

9

|

INSPECT CAN LINE BETWEEN RADAR UNIT AND CONNECTOR C-42 FOR SHORT TO POWER SUPPLY

• Measure the voltage at radar unit terminals D and C.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 51.

|

|

No

|

Go to the next step.

|

||

|

10

|

INSPECT RADAR UNIT FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the radar unit connector.

• Connect connector C-42.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the radar unit because there is a short to the power supply in the radar unit.

|

|

No

|

Repair or replace the wiring harness between radar unit and connector C-42 because the wiring harness is shorted to the power supply.

|

||

|

11

|

INSPECT CAN LINE BETWEEN CONNECTORS C-43, C-44 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connectors C-43, C-44.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 16.

|

|

No

|

Go to the next step.

|

||

|

12

|

INSPECT CAN LINE BETWEEN ADAPTIVE LED HEADLIGHTS CONTROL MODULE / AUTO LEVELING CONTROL MODULE AND CONNECTORS C-43, C-44 FOR SHORT TO POWER SUPPLY

• Measure the voltage at adaptive LED headlights control module / auto leveling control module terminals A and B.(JM0 TC*****# 100001-399999, JM6 TC*****# 100001-399999)

• Measure the voltage at adaptive LED headlights control module / auto leveling control module terminals L and M (JM0 TC*****# 400001-, JM6 TC*****# 400001-)

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 14.

|

|

No

|

Go to the next step.

|

||

|

13

|

INSPECT ADAPTIVE LED HEADLIGHTS CONTROL MODULE / AUTO LEVELING CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Connect connectors C-43, C-44.

• Disconnect the adaptive LED headlights control module / auto leveling control module connector.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the adaptive LED headlights control module / auto leveling control module because there is a short to the power supply in the adaptive LED headlights control module / auto leveling control module.

|

|

No

|

Repair or replace the wiring harness between the adaptive LED headlights control module / auto leveling control module and connectors C-43, C-44 because the wiring harness is shorted to the power supply.

|

||

|

14

|

INSPECT CAN LINE BETWEEN DC-DC CONVERTER (i-ELOOP) AND CONNECTORS C-43, C-44 FOR SHORT TO POWER SUPPLY

• Measure the voltage at DC-DC converter (i-ELOOP) terminals 1M and 1N.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between the front body control module (FBCM) and connectors C-43, C-44 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

15

|

INSPECT DC-DC CONVERTER (i-ELOOP) FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Connect connectors C-43, C-44.

• Disconnect the DC-DC converter (i-ELOOP) connector.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the DC-DC converter (i-ELOOP) because there is a short to the power supply in the DC-DC converter (i-ELOOP).

|

|

No

|

Repair or replace the wiring harness between the DC-DC converter (i-ELOOP) and connectors C-43, C-44 because the wiring harness is shorted to the power supply.

|

||

|

16

|

INSPECT CAN LINE BETWEEN CONNECTOR C-07 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-07.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between the connector C-07 and connectors C-43, C-44 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

17

|

INSPECT CAN LINE BETWEEN CONNECTORS C-47, C-48 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connectors C-47, C-48.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 20.

|

||

|

18

|

INSPECT CAN LINE BETWEEN ELECTRIC PARKING BRAKE CONTROL MODULE AND CONNECTORS C-47, C-48 FOR SHORT TO POWER SUPPLY

• Measure the voltage at electric parking brake control module terminals 2G and 2F.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between connectors C-47, C-48 and connector C-07 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

19

|

INSPECT ELECTRIC PARKING BRAKE CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the electric parking brake control module connector.

• Connect connectors C-47, C-48.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the electric parking brake control module because there is a short to the power supply in the electric parking brake control module.

|

|

No

|

Repair or replace the wiring harness between the electric parking brake control module and connectors C-47, C-48 because the wiring harness is shorted to the power supply.

|

||

|

20

|

INSPECT CAN LINE BETWEEN CONNECTORS C-54, C-55 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connectors C-54, C-55.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 24.

|

||

|

21

|

INSPECT CAN LINE BETWEEN POSITION MEMORY CONTROL MODULE AND CONNECTORS C-54, C-55 FOR SHORT TO POWER SUPPLY

• Measure the voltage at position memory control module terminals 1C and 1E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between the connectors C-47, C-48 and connectors C-54, C-55 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

22

|

INSPECT CAN LINE BETWEEN POSITION MEMORY CONTROL MODULE AND CONNECTOR C-29 FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-29.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at position memory control module terminals 1C and 1E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between the connectors C-54, C-55 and connector C-29 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

23

|

INSPECT POSITION MEMORY CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the position memory control module connector.

• Connect connector C-29.

• Connect connectors C-54, C-55.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the position memory control module because there is a short to the power supply in the position memory control module.

|

|

No

|

Repair or replace the wiring harness between the position memory control module and connector C-29 because the wiring harness is shorted to the power supply.

|

||

|

24

|

INSPECT CAN LINE BETWEEN CONNECTORS C-51, C-52 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connectors C-51, C-52.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 31.

|

||

|

25

|

INSPECT CAN LINE BETWEEN AUDIO AMPLIFIER AND CONNECTORS C-51, C-52 FOR SHORT TO POWER SUPPLY

• Measure the voltage at audio amplifier terminals 2L and 2N.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 27.

|

|

No

|

Go to the next step.

|

||

|

26

|

INSPECT AUDIO AMPLIFIER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the audio amplifier connector.

• Connect connectors C-51, C-52.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the audio amplifier because there is a short to the power supply in the audio amplifier.

|

|

No

|

Repair or replace the wiring harness between the audio amplifier and connectors C-51, C-52 because the wiring harness is shorted to the power supply.

|

||

|

27

|

INSPECT CAN LINE BETWEEN 4WD CONTROL MODULE AND CONNECTORS C-51, C-52 FOR SHORT TO POWER SUPPLY

• Measure the voltage at 4WD control module terminals G and H.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 29.

|

|

No

|

Go to the next step.

|

||

|

28

|

INSPECT 4WD CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the 4WD control module connector.

• Connect connectors C-51, C-52.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the 4WD control module because there is a short to the power supply in the 4WD control module.

|

|

No

|

Repair or replace the wiring harness between the 4WD control module and connectors C-51, C-52 because the wiring harness is shorted to the power supply.

|

||

|

29

|

INSPECT CAN LINE BETWEEN POWER LIFTGATE (PLG) CONTROL MODULE AND CONNECTOR C-19 FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-19.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at power liftgate (PLG) control module terminals 1B and 1A.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between connector C-19 and connectors C-54, C-55 and connectors C-51, C-52 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

30

|

INSPECT POWER LIFTGATE (PLG) CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the power liftgate (PLG) control module connector.

• Connect connector C-19.

• Connect connectors C-51, C-52.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the power liftgate (PLG) control module because there is a short to the power supply in the power liftgate (PLG) control module.

|

|

No

|

Repair or replace the wiring harness between the power liftgate (PLG) control module and connector C-19 because the wiring harness is shorted to the power supply.

|

||

|

31

|

INSPECT CAN LINE BETWEEN CONNECTOR C-14 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-14.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Repair or replace the wiring harness between connector C-14 and connectors C-51, C-52 because the wiring harness is shorted to the power supply.

|

|

No

|

Go to the next step.

|

||

|

32

|

INSPECT CAN LINE BETWEEN CONNECTOR C-14 AND CONNECTOR C-45 FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-45.

• Connect connector C-14.

• Connect connectors C-51, C-52.

• Connect connectors C-54, C-55.

• Connect connectors C-47, C-48.

• Connect connector C-07.

• Connect connectors C-43, C-44.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at front body control module (FBCM) terminals 2K and 2I (wiring harness side).

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between the connector C-14 and connector C-45 and DLC-2 because the wiring harness is shorted to the power supply.

|

||

|

33

|

INSPECT CAN LINE BETWEEN CONNECTOR C-45 AND INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Measure the voltage at instrument cluster terminals 1B and 1D.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 45.

|

||

|

34

|

INSPECT CAN LINE BETWEEN EPS CONTROL MODULE AND CONNECTOR C-45 FOR SHORT TO POWER SUPPLY

• Measure the voltage at EPS control module terminals 2B and 2D.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 36.

|

|

No

|

Go to the next step.

|

||

|

35

|

INSPECT EPS CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the EPS control module connector.

• Connect connector C-45.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the EPS control module because there is a short to the power supply in the EPS control module.

|

|

No

|

Repair or replace the wiring harness between the EPS control module and connector C-45 because the wiring harness is shorted to the power supply.

|

||

|

36

|

INSPECT CAN LINE BETWEEN START STOP UNIT AND CONNECTOR C-45 FOR SHORT TO POWER SUPPLY

• Measure the voltage at start stop unit terminals 2M and 2O.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 38.

|

|

No

|

Go to the next step.

|

||

|

37

|

INSPECT START STOP UNIT FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the start stop unit connector.

• Connect connector C-45.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the start stop unit because there is a short to the power supply in the start stop unit.

|

|

No

|

Repair or replace the wiring harness between the start stop unit and connector C-45 because the wiring harness is shorted to the power supply.

|

||

|

38

|

INSPECT CAN LINE BETWEEN CONNECTIVITY MASTER UNIT (CMU) AND CONNECTOR C-45 FOR SHORT TO POWER SUPPLY

• Measure the voltage at connectivity master unit (CMU) terminals 2E and 2F.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 40.

|

|

No

|

Go to the next step.

|

||

|

39

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the connectivity master unit (CMU) connector.

• Connect connector C-45.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the connectivity master unit (CMU) because there is a short to the power supply in the connectivity master unit (CMU).

|

|

No

|

Repair or replace the wiring harness between the connectivity master unit (CMU) and connector C-45 because the wiring harness is shorted to the power supply.

|

||

|

40

|

INSPECT CAN LINE BETWEEN ACTIVE DRIVING DISPLAY AND CONNECTOR C-45 FOR SHORT TO POWER SUPPLY

• Measure the voltage at active driving display terminals I and L.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 42.

|

|

No

|

Go to the next step.

|

||

|

41

|

INSPECT ACTIVE DRIVING DISPLAY FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the active driving display connector.

• Connect connector C-45.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the active driving display because there is a short to the power supply in the active driving display.

|

|

No

|

Repair or replace the wiring harness between the active driving display and connector C-45 because the wiring harness is shorted to the power supply.

|

||

|

42

|

INSPECT CAN LINE BETWEEN TUNER AND AMP UNIT (TAU) AND CONNECTOR C-45 FOR SHORT TO POWER SUPPLY

• Measure the voltage at tuner and amp unit (TAU) terminals 2E and 2C.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 44.

|

|

No

|

Go to the next step.

|

||

|

43

|

INSPECT TUNER AND AMP UNIT (TAU) FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the tuner and amp unit (TAU) connector.

• Connect connector C-45.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the tuner and amp unit (TAU) because there is a short to the power supply in the tuner and amp unit (TAU).

|

|

No

|

Repair or replace the wiring harness between the tuner and amp unit (TAU) and connector C-45 because the wiring harness is shorted to the power supply.

|

||

|

44

|

INSPECT SAS CONTROL MODULE FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the SAS control module connector.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at SAS control module terminals 3B and 3C (wiring harness side).

• Is the voltage 0 V?

|

Yes

|

Replace the SAS control module because there is a short to the power supply in the SAS control module.

|

|

No

|

Repair or replace the wiring harness between SAS control module and connector C-45 because the wiring harness is shorted to the power supply.

|

||

|

45

|

INSPECT CAN LINE BETWEEN CONNECTOR C-45 AND CONNECTOR C-16 FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-16.

• Connect connector C-45.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between connector C-45 and connector C-16 because the wiring harness is shorted to the power supply.

|

||

|

46

|

INSPECT CAN LINE BETWEEN LASER SENSOR / FORWARD SENSING CAMERA (FSC) AND CONNECTOR C-16 FOR SHORT TO POWER SUPPLY

• Measure the voltage at laser sensor terminals D and C (with laser sensor).

• Measure the voltage at forward sensing camera (FSC) terminals E and C (with forward sensing camera (FSC)) (connector 10-pin type).

• Measure the voltage at forward sensing camera (FSC) terminals M and N (with forward sensing camera (FSC)) (connector 12-pin type).

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to Step 50.

|

|

No

|

Go to the next step.

|

||

|

47

|

INSPECT LASER SENSOR FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the laser sensor connector.

• Connect connector C-16.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the laser sensor because there is a short to the power supply in the laser sensor.

|

|

No

|

• Go to the next step. (connector 10-pin type)

• Go to Step 49. (connector 12-pin type)

|

||

|

48

|

INSPECT CAN LINE BETWEEN CONNECTOR C-34 AND FORWARD SENSING CAMERA (FSC) FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect connector C-34.

• Connect connector C-16.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness between connector C-34 and connector C-16 because the wiring harness is shorted to the power supply.

|

||

|

49

|

INSPECT FORWARD SENSING CAMERA (FSC) FOR SHORT TO POWER SUPPLY

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Disconnect the forward sensing camera (FSC) connector.

• Connect the connector C-34.(connector 10-pin type)

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5—3.5 V?

|

Yes

|

Replace the forward sensing camera (FSC) because there is a short to the power supply in the forward sensing camera (FSC).

|

|

No

|

• Repair or replace the wiring harness between the forward sensing camera (FSC) and connector C-34 because the wiring harness is shorted to the power supply. (connector 10-pin type)

• Repair or replace the wiring harness between the forward sensing camera (FSC) and connector C-16 because the wiring harness is shorted to the power supply. (connector 12-pin type)

|

||

|

50

|

INSPECT INSTRUMENT CLUSTER FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the instrument cluster connector.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the instrument cluster because there is a short to the power supply in the instrument cluster.

|

|

No

|

Repair or replace the wiring harness between the instrument cluster and connector C-16 because the wiring harness is shorted to the power supply.

|

||

|

51

|

INSPECT PCM FOR SHORT TO POWER SUPPLY

• Switch the ignition off (LOCK).

• Disconnect the negative battery terminal.

• Disconnect the PCM connector.

• Connect connector C-42.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off).

• Measure the voltage at DLC-2 terminals F and E.

• Is the voltage between 1.5 — 3.5 V?

|

Yes

|

Replace the PCM because there is a short to the power supply in the PCM.

|

|

No

|

Repair or replace the wiring harness between the PCM and connector C-42 because the wiring harness is shorted to the power supply.

|

||