|

ENGINE REMOVAL/INSTALLATION [SKYACTIV-G 2.5T]

id0110q8800400

1. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

2. Remove the front under cover No.1 and No.2. (See FRONT UNDER COVER No.1 REMOVAL/INSTALLATION.) (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

3. Remove the front splash shield. (See FRONT SPLASH SHIELD REMOVAL/INSTALLATION.)

4. Drain the engine coolant. (See ENGINE COOLANT REPLACEMENT [SKYACTIV-G 2.5T].)

5. Drain the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GW6A-EL, GW6AX-EL].)

6. Drain the transfer oil. (4WD) (See TRANSFER OIL REPLACEMENT [GW6AX-EL].)

7. Remove the front wheels and tires. (See WHEEL AND TIRE REMOVAL/INSTALLATION.)

8. Remove the plug hole plate. (See PLUG HOLE PLATE REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

9. Remove the air cleaner, air hose and fresh air duct as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

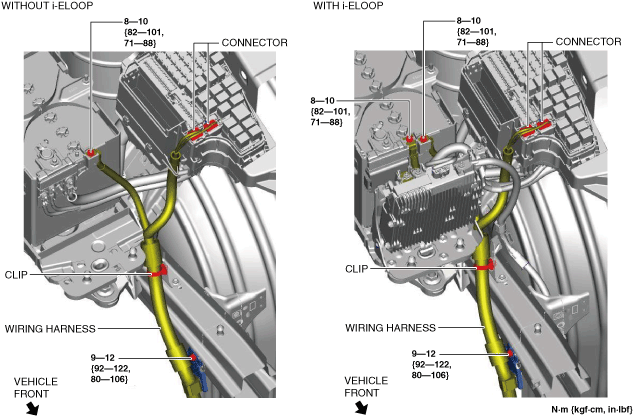

10. Remove the bolt, nut, clip and connector shown in the figure, and set the wiring harness aside.

ac9wzw00003836

|

11. Set the DC-DC converter (i-ELOOP) aside in the direction of the arrow shown in the figure with the wiring harness connected. (with i-ELOOP) (See DC-DC CONVERTER (i-ELOOP) REMOVAL/INSTALLATION [i-ELOOP].)

ac9wzw00003837

|

12. Remove the battery and battery tray. (See BATTERY REMOVAL/INSTALLATION.)

13. Remove the air inlet pipe. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

14. Remove the turbocharger air outlet pipe and charge air cooler inlet hose. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

15. Remove the charge air cooler outlet pipe and charge air cooler outlet hose as a single unit. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

16. Disconnect the selector cable. (See AUTOMATIC TRANSAXLE SHIFT MECHANISM REMOVAL/INSTALLATION.)

17. Disconnect the brake vacuum hose. (See VACUUM HOSE REMOVAL/INSTALLATION [L.H.D.].) (See VACUUM HOSE REMOVAL/INSTALLATION [R.H.D.].)

18. Disconnect the clip shown in the figure from the protector.

ac9wzw00004457

|

19. Disconnect the evaporative hose. (See PURGE SOLENOID VALVE REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

20. Disconnect the fuel hose. (See QUICK RELEASE CONNECTOR REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

21. Disconnect the upper radiator hose.

ac9uuw00006344

|

22. Remove the lower radiator hose and pipe component using the following procedure:

ac9uuw00006345

|

ac9wzw00005706

|

ac9uuw00007431

|

ac9uuw00006348

|

23. Disconnect the heater hoses.

ac9uuw00006349

|

24. Remove the generator drive belt. (See DRIVE BELT REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

25. Disconnect the water hose from water-cooled oil cooler.

ac9uuw00006350

|

26. Disconnect the oil hoses from radiator. (if equipped) (See OIL COOLER REMOVAL/INSTALLATION [GW6A-EL, GW6AX-EL].)

27. Remove the A/C compressor with the cooler hose still connected and secure it using wire or rope so that it is out of the way. (See A/C COMPRESSOR REMOVAL/INSTALLATION.)

28. Remove the TWC installation nuts (WU-TWC side) and secure the TWC using wire or rope so that it is out of the way (2WD). (See EXHAUST SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

29. Remove the TWC. (4WD) (See EXHAUST SYSTEM REMOVAL/INSTALLATION [SKYACTIV-G 2.5T].)

30. Remove the propeller shaft. (4WD) (See PROPELLER SHAFT REMOVAL/INSTALLATION.)

31. Disconnect the front drive shaft (LH) from the transaxle side and set the drive shaft (LH) out of the way. (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

32. Disconnect the front drive shaft (RH) from the transaxle side and set the drive shaft (RH) out of the way. (2WD) (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

33. Remove the front drive shaft (RH). (4WD) (See FRONT DRIVE SHAFT REMOVAL/INSTALLATION.)

34. Remove the bolt and set the ground cable aside.

ac9uuw00006352

|

35. Remove in the order indicated in the table.

2WD

ac9uuw00006353

|

|

1

|

Bracket plate

|

|

2

|

No.1 engine mount rubber, front crossmember component

|

|

3

|

No.1 engine mount bracket

|

|

4

|

No.4 engine mount bracket

|

|

5

|

No.3 engine mount

|

|

6

|

Engine, transaxle

|

4WD

ac9uuw00006354

|

|

1

|

Bracket plate

|

|

2

|

No.1 engine mount rubber, front crossmember component

|

|

3

|

No.4 engine mount bracket

|

|

4

|

No.3 engine mount

|

|

5

|

Engine, transaxle

|

36. Install in the reverse order of removal.

37. Refill the transfer oil. (4WD) (See TRANSFER OIL REPLACEMENT [GW6AX-EL].)

38. Refill the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [GW6A-EL, GW6AX-EL].)

39. Refill the engine coolant. (See ENGINE COOLANT REPLACEMENT [SKYACTIV-G 2.5T].)

40. Start the engine, and inspect and adjust the following:

No.1 Engine Mount Rubber, Front Crossmember Component Removal Note

1. Disconnect the service plug. (with i-ELOOP) (See SERVICE PLUG DISCONNECTION/CONNECTION [i-ELOOP].)

2. Disconnect the generator terminal B cable. (with i-ELOOP) (See GENERATOR REMOVAL/INSTALLATION [WITH i-ELOOP (SKYACTIV-G 2.5T)].)

3. Remove the bolts shown in the figure and remove the wiring harness bracket. (with i-ELOOP)

ac9wzw00003838

|

4. Remove the clips shown in the figure and set the wiring harness aside. (with i-ELOOP)

ac9wzw00003839

|

5. Loosen the No.1 engine mount rubber installation bolt (front crossmember side) shown in the figure.

2WD

ac9uuw00006355

|

4WD

ac9uuw00006356

|

6. Remove the No.1 engine mount rubber and the front crossmember component as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION.)

No.3 Engine Mount, No.4 Engine Mount Bracket Removal Note

1. Remove the clip and bolt shown in the figure and set the ground cable aside.

ac9uuw00006357

|

2. Set the PCM wiring harness and PCM component aside using the following procedure:

ac9wzw00005518

|

ac9uuw00006359

|

ac9uuw00006360

|

3. Remove the nut shown in the figure and set the cooler hose aside.

ac9wzw00005519

|

4. Disconnect the ground cable shown in the figure.

ac9uuw00006362

|

5. Disconnect the clip shown in the figure.

ac9uuw00006363

|

6. Secure the engine and transaxle using a commercially available engine lifter.

ac9wzw00005707

|

7. Remove the No.4 engine mount bracket.

8. Remove the No.3 engine mount.

Engine Mount Installation Note

1. Tighten the engine front cover stud bolts.

ac9uuw00006364

|

2. Tighten the transaxle stud bolts.

ac3wzw00000647

|

3. Secure the engine and transaxle using a commercially available engine lifter.

ac9wzw00005707

|

4. Temporarily tighten the No.3 engine mount installation bolts and nuts using the following procedure:

ac9uuw00006365

|

ac9uuw00006366

|

5. Temporarily tighten the No.4 engine mount bracket installation bolt and nuts using the following procedure:

ac9uuw00006367

|

ac9uuw00006368

|

6. Install the No.1 engine mount rubber and the front crossmember component as a single unit. (See FRONT CROSSMEMBER REMOVAL/INSTALLATION.)

7. Temporarily tighten the following parts:

ac9uuw00006369

|

ac9uuw00006370

|

8. Tighten the No.1 engine mount bracket and bracket plate installation bolts in the order shown in the figure. (2WD)

ac9uuw00006371

|

9. Tighten the No.3 engine mount installation bolts and nuts in the order shown in the figure.

ac9uuw00006372

|

Tightening torque

|

No. |

Tightening torque |

|---|---|

|

1

|

76—95 N·m {7.8—9.6 kgf·m, 57—70 ft·lbf}

|

|

2

|

82—95 N·m {8.4—9.6 kgf·m, 61—70 ft·lbf}

|

|

3

|

49—65 N·m {5.0—6.6 kgf·m, 37—47 ft·lbf}

|

10. Tighten the No.4 engine mount bracket installation bolt and nuts in the order shown in the figure.

ac9uuw00006373

|

Tightening torque

|

No. |

Tightening torque |

|---|---|

|

1, 2, 3

|

92—116 N·m {9.4—11 kgf·m, 68—85 ft·lbf}

|

|

4

|

81—99 N·m {8.3—10 kgf·m, 60—73 ft·lbf}

|

11. Tighten the No.1 engine mount rubber installation bolts.

2WD

ac9uuw00006374

|

4WD

ac9uuw00006375

|

12. Install the clips shown in the figure. (with i-ELOOP)

ac9wzw00004458

|

13. Install the wiring harness bracket shown in the figure. (with i-ELOOP)

ac9wzw00003840

|

14. Connect the generator terminal B cable. (with i-ELOOP) (See GENERATOR REMOVAL/INSTALLATION [WITH i-ELOOP (SKYACTIV-G 2.5T)].)

15. Install the service plug. (with i-ELOOP) (See SERVICE PLUG DISCONNECTION/CONNECTION [i-ELOOP].)

16. Connect the clip shown in the figure.

ac9uuw00006363

|

17. Install the ground cable shown in the figure.

ac9uuw00006376

|

18. Return the cooler hose that was set aside to its original position and tighten the nut.

ac9wzw00005520

|

19. Install the PCM component using the following procedure:

ac9uuw00006378

|

ac9uuw00006379

|

ac9uuw00007432

|

20. Install the ground cable shown in the figure.

ac9uuw00006381

|